March 10, 2025

ASHWAUBENON – As the market changes, Andrew Schipke, vice president of marketing and strategic sales for BW Converting – said the envelope converting, printing and inserting technology company has changed with it to keep up with the needs of customers.

“We listen to the marketplace, and we try to project out three or four years ahead of time, where we think (about) products’ life cycles, (based on) what the market wants,” he said. “The customer base has changed its needs – (they are) looking for easier-to-operate machinery and more compact machinery that uses less floor space.”

During this process, Schipke said BW Converting developed a new platform – “called the 800 series.”

An extension to that platform, he said, is the company’s recently introduced BB 816+ high-performance mail inserter.

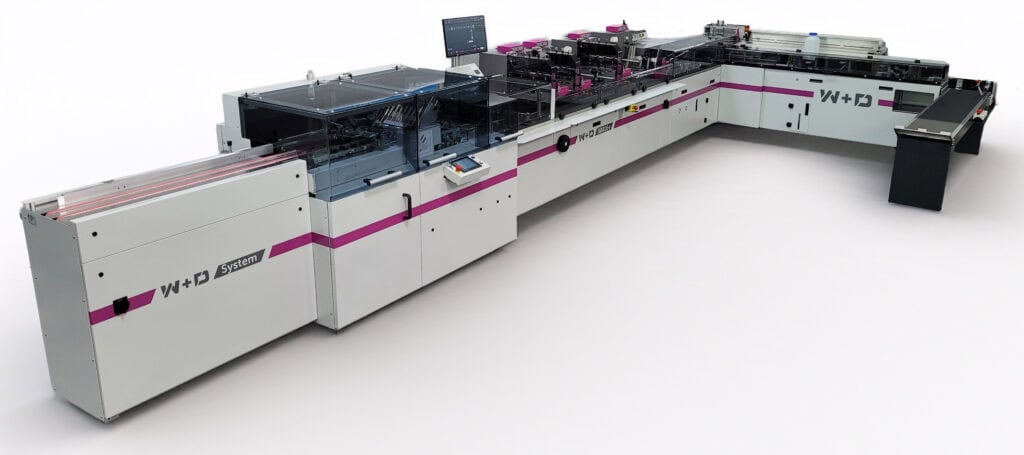

This new addition to the 800 series platform of servo-driven, easier-to-operate mail inserters – which was officially announced at Hunkeler Innovation Days held last month in Lucerne, Switzerland – is built for direct mail, transactional mail and specialized applications, such as vote by mail, offering the highest levels of integrity and adaptability for customized solutions.

Schipke said the BB 816+ is the next-generation successor to the BB700 mail-inserting workhorse, with hundreds of units installed worldwide.

“It replaces some of the legacy equipment,” he said.

The BB 816+, Schipke said, introduces advancements in ease of use, speed of changeover, mail product control and automation – further solidifying BW Converting and its W+D brand as an “innovator with unparalleled knowledge of the performance characteristics of the envelope.”

“Again, we’re looking at making improvements in simplicity of operation,” he said. “It’s really just an ability to fine-tune that product line to reach a new customer base.”

Mail, Schipke said, isn’t necessarily growing in size in terms of overall volume – “yet the requirements by a lot of the mail houses and our users are changing.”

“So, we need to respond to those need changes if we’re going to stay in a leadership position in this marketplace,” he said.

More complex

Since COVID-19, Schipke said there has been a push for more user-friendly machinery.

“Product production efficiency is critical, speed is critical – depending on the product, whether it’s transactional or direct mail,” he said. “It has become more complex. It has become more personalized. A lot of changes (are) going on in physical mail that require different strategies on machinery. The term I guess we used at a recent large trade show was ‘the ability to do more with less.’”

Today, Schipke said companies are looking for “very flexible machines that can do all kinds of pieces.”

“Mail is no longer just a standard-sized envelope,” he said. “It’s all kinds of envelopes now. There’s all kinds of creative approaches that the marketing professionals are throwing into the market space that companies are now using.”

The key, Schipke said, is to stay on top of where the market is headed.

“Like Wayne Gretzky said: ‘You skate to where the puck is going to be,’” he said. “That’s what we’re trying to do.”

Versatility, scalability

Schipke said the BB 816+ is a “future-proof inserting investment” due to the new 800 series platform’s modular scalability capabilities.

“The BB 816+ can be configured to smaller floor spaces and expanded for changing market demands,” he said.

Schipke said it also offers interchangeability with BW Converting’s flagship inserter – the W+D BB820+, a 20,000-piece-per-hour machine model.

The BB 816+, he said, operates at up to 16,000 pieces per hour across the widest format range of any high-performance inserter.

“This highly flexible system can handle product thicknesses up to 6/10 inch (15 millimeters),” he said.

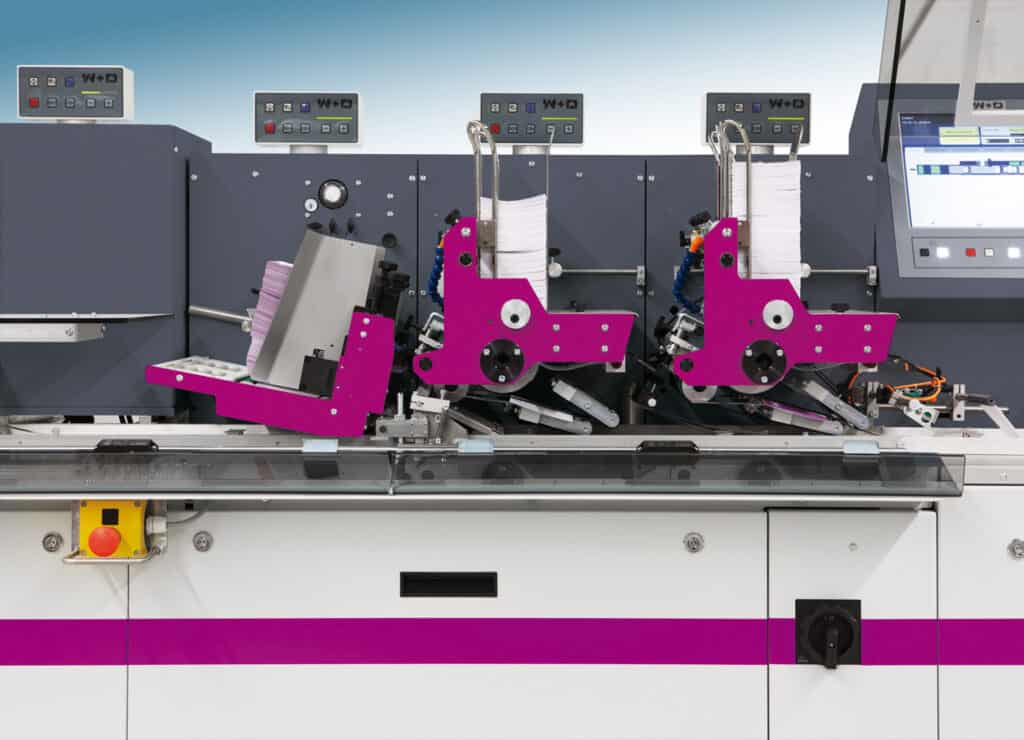

Schipke said key innovations of the BB 816+ include:

- A dual lug chain for enhanced product control at high speeds

- An upgraded insertion module with an optimized insert pusher assembly

- Advanced envelope feeder

- Size-dependent linear speed control to ensure seamless operation across varying envelope dimensions

The system, he said, also features BW Converting’s patented W+D Auto Mismatch Recovery Technology, which handles multiple personalized products with limited or no operator intervention.

Schipke said with the BB 816+, BW Converting is “moving a little bit down market.”

“As a piece of equipment made in Germany, we have that Mercedes mystique,” he said. “So this is like the Baby Benz.”

Sometimes, Schipke said BW Converting’s inserters “are outside the price reach of smaller mailing houses.”

“So, this is an extension of a strategy to take the new platform with the flagship machine – the 820 and 820+ – and take it down market,” he said. “It has a little smaller footprint, because a lot of smaller commercial shops don’t have a lot of space.”

Though the BB 816+ is “a little bit slower,” Schipke said it offers the same amount of flexibility and features as the larger models.

“We took the speed down, but still offer that very wide range of product (capabilities) that can be run across this machine at a really low total cost of operation,” he said.

The right audience

Though Switzerland’s Hunkeler Innovation Days isn’t the latest trade show regarding printing, Schipke said “if you’re going to make an announcement, you make it there.”

“There will be what we call ‘the industry leaders, the change makers’ at these events,” he said. “It’s known as a show where you see a lot of firsts. It’s one of those shows where, if you’ve got something to launch, you’re going to have the right audience in attendance.”

Schipke said Hunkeler Innovation Days is an important show, “because it is a digital print show surrounded by what we call a lot of ‘finishing technologies’ that all support digital print.”

Since BW Converting is moving in the direction that the market wants with the launch of the BB 816+, Schipke said the company has received a lot of positive feedback.

The plan, he said, is to officially launch the BB 816+ at a large trade show in the U.S. later this year.

“There’s a very big U.S. show in North America here in October and our plan is to bring the BB 816+ to that show,” he said. “This is where you get the entire U.S. mailing industry (in attendance), which is the largest in the world.”

In terms of mailing markets, Schipke said that’s an important factor to understand.

“For a size perspective, if you take all EU countries, they represent somewhere in the area of 40 billion units total,” he said. “The U.S. market is a little more than 100 billion total units – so you can see the difference.”

That difference in size, Schipke said, equates to different needs.

“The European market is much different for a number of reasons,” he said. “A lot of the mailing market is privatized. There are various privacy laws – personalization is not seen at a scale in Europe like it is here in the U.S.”

Schipke said the plan is to utilize BW Converting’s Green Bay location for demonstrations.

“Green Bay has now become our hub of excellence for product demonstrations for all of the brands in the BW Converting portfolio,” he said. “A lot of people that are going to look at this are going to want to test run their products, or see private demos with specific unique characteristics – and it’s very difficult to take them into another user’s site for those.”

With the immediate reaction to the product’s design being positive – “we’ve already sold a BB 816+ based on the concept, which was shipped out at the end of last month” – Schipke said it’s important to create opportunities for people “to put their hands on it and see it.”

“And that’s the next stage of where we’re at with this release,” he said.

Having the Green Bay location focused on being a hub of excellence, Schipke said, provides BW Converting with an opportunity to “show people how they can use and leverage these products.”

“And that’s very exciting,” he said.

For more on BW Converting or its new BB 816+ high-performance mail inserter, visit bwconverting.com.

‘At the end of the day, we do more than manage health care’

‘At the end of the day, we do more than manage health care’ New Fawn Creek Winery owners seek to showcase hidden gem

New Fawn Creek Winery owners seek to showcase hidden gem