June 9, 2025

TOMAHAWK – Steve Daigle, founder of Daigle Brothers in Tomahawk, said he is excited about every new project that has come his way in the last 35-plus years.

However, the company’s latest project, he said, is particularly exciting.

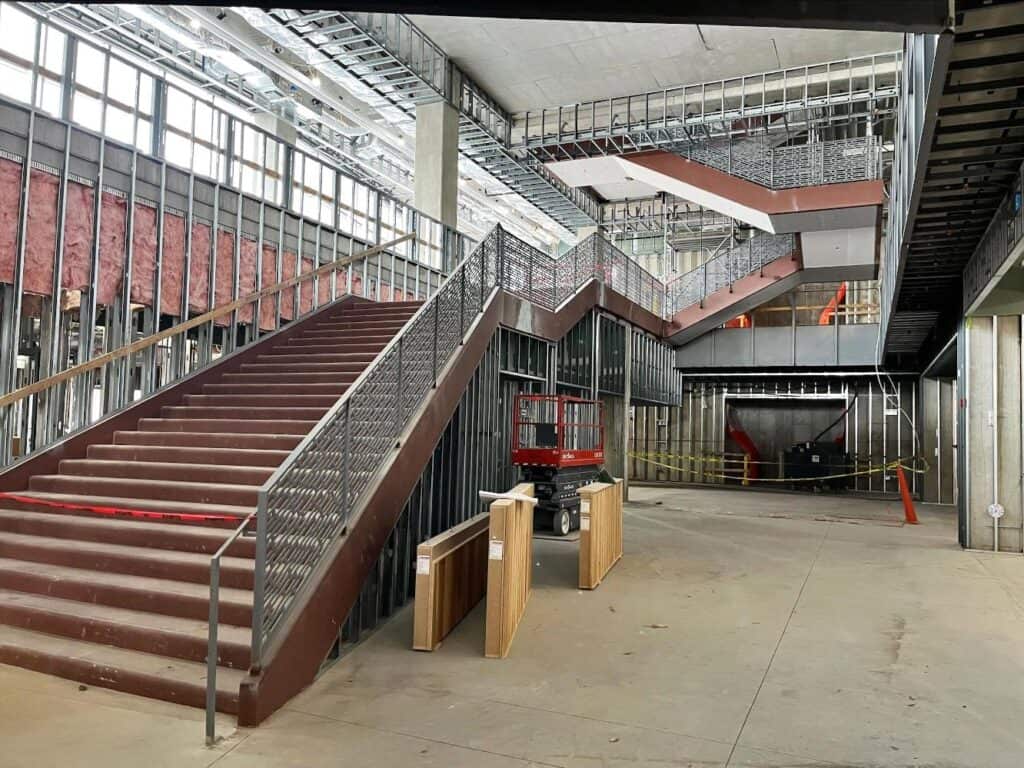

Steve said the structural steel fabricator business has been chosen to help build the new 100,000-square-foot Wisconsin History Center museum – which is currently under construction on the Capitol square in Madison, replacing the Wisconsin Historical Society museum.

A few more details

Daigle Brothers provides structural steel fabrication for several markets, including health care, commercial, residential and education, as well as custom fabrication services from ornamental staircase railings to large yard trailers and boat ramps.

The company, Steve said, primarily serves clients in Wisconsin, but has also supplied steel for projects across the country.

Pretty good, he said, for a guy who got his start in the industry at age 20 – doing business with South Side Welding and Sandblasting in Tomahawk as a subcontractor

“About a year later, I was at a friend’s house one day, when Jim (the business’ owner) pulled up in his truck and said ‘get in,’” he said. “He said he was selling the business, and I could either buy it or look for another job. So, I bought it.”

Steve said his entrepreneurial spirit for resilience and persistence kicked in right away when the business promptly lost its primary customer, a road machinery repair account.

“But when I look back, it was the best thing that ever happened to me,” he said. “Here’s a 21-year-old kid who has no work, and he’s got to try to be creative to make stuff that people might buy. I started doing any and every repair work I could find.”

Self-reliance, Steve said, came naturally for him.

As the youngest of 10, he said he lost his dad at the age of 13.

“I watched mom pull herself through it, and I learned I could do it, too,” he said.

Steve said his first big break came from a local auto repair shop, which needed to subcontract some trailer repair work.

The work, he said, provided some much-needed consistency and stability for the business.

“They were the best customer I ever had,” he said. “To this day, we’re good friends. It was a great relationship. They really taught me a lot about doing a good job, how to run a business with integrity and how to get paid what you’re worth.”

In 1991, Steve said he partnered with his brother Lee and renamed the business Daigle Brothers Southside Welding and Sandblasting.

Another big break, he said, occurred when Louisiana Pacific relocated a plant from Colorado to Tomahawk.

“We did a lot of work for them,” he said. “We hired a few people to help keep up. This is when I learned about structural steel, building stairs, railings and platforms and other construction-related services.”

Steve said he would hear “these stories about swinging steel and setting steel and doing crane work” for those who had experience in the construction industry – including one of his brothers – and “was really inspired by that.”

From that point on, he said his mission was to secure a major build project all on his own.

That opportunity, Steve said, presented itself in 1992 when the City of Tomahawk started seeking bids for a new middle school.

Knowing nothing about architectural prints, he said he got to work seeking help from others, and luck would have it that a contact who helped build the new Louisiana Pacific facility was in the area and “taught me a ton in one day.”

Steve – at the ripe old age of 25 – got the contract.

He said it was a major turning point for the business, which eventually became known as simply Daigle Brothers.

The company continued to grow, Steve said – promoting him to hire more people and move into a new building in 1994.

In 1998, he said he bought his brother’s share of the business and began a number of growth initiatives, which eventually included a 14,000-square-foot expansion, a new paint shop and the launch of an in-house detailing department.

Large-scale projects

A major project Daigle Brothers is currently working on, Steve said, is providing structural steel for the new $3 billion Eli Lilly expansion in Kenosha County.

Other larger-scale projects the company has been involved in over the years, he said, include:

- The Health Sciences Center at Northcentral Technical College in Wausau

- Orion Energy in Manitowoc

- The Peninsula Players Theater in Fish Creek

- Mercy Clinic East in Janesville

- Medical center in Appleton

The medical center project in Appleton, Steve said, launched the company into the CNC machining business, further expanding its capabilities.

“We were awarded the medical center in 2008,” he said. “It was a huge project and our biggest job at the time. It had a large amount of what we call ‘jumbo columns.’ The flanges are about three inches thick, and there were just these huge columns – we had to drill through three inches of steel, and each column had like 150 holes. And after we were awarded the job, I said, ‘Well, we’re going to have to get some longer drill bits.’”

Steve said Daigle Brothers also worked on the Nicholas Recreation Center near the Kohl Center in Madison.

“That was a gigantic project,” he said. “It was 2,500 tons of structural steel and 25,000 hours of work. The total contract ended up being almost $10 million – our largest to date.”

Facility investments, capabilities

To support complex, large-scale projects, Steve said Daigle Brothers has made major investments in infrastructure and process improvements, including:

- A new marshalling yard for staging and preassembly, completed this spring

- Demolished and raised the height of its original building to eliminate operational bottlenecks

- Upgraded the facility’s electrical systems to support increased capacity and new equipment

- Reconfigured its production flow for lean, efficient throughput

- Installed a 337 kW solar power system, reinforcing the company’s sustainability commitment

- Converted all welders to dual-feed wire feeders, enhancing productivity and weld precision

- Added two overhead cranes, increasing throughput and handling capabilities

- Installed eight Slinger-brand beam rotators to improve work station efficiency and support rigorous quality inspections

Steve said these enhancements reflect Daigle Brothers’ continuous improvement culture and readiness to deliver exceptional results.

An ever-evolving industry

Like many long-running businesses, Steve said Daigle Brothers experienced firsthand the shift from doing everything by paper and pencil to a nearly all-digital shop.

Today, he said staff use state-of-the-art software for blueprint design and project tracking, as well as structural steel design and detailing.

Other in-house technologies, Steve said, include automated laser cuts for the company’s custom railing and other fabrication projects.

Diversifying his expertise even more, Steve said he holds the U.S. patent for a hydraulic shoveling platform used on a line of truck and trailer bed inserts called Hot Patch that he developed.

He said the units are used for heating cold asphalt patch material to prolong the life of the mix during the work day.

This is a separate business, he said, called Five D Industries.

‘Find what inspires you’

Looking back at all Daigle Brothers has accomplished in its nearly four decades in business, Steve said the key to the business’s success is “hiring exceptional people who not only know how to keep pace with changing technology but hunger for it.”

Furthermore, he said his wife, Marie, and family have been a great source of support, with his nephew currently serving as plant manager.

“Marie has been my emergency go-to person since day one – from creating last-minute quotes when we first entered the bidding world, to helping out in the accounting department,” he said. “She has sound judgement, and the team always respects her view of the big picture.”

Steve said this time of year is often viewed as a time of transition, with many young people graduating.

To help support the journeys ahead for these new graduates, Steve said he and Marie award scholarships to high school graduates pursuing a degree in the technical fields.

Steve said this allows him to remind the next generation about the importance of believing in themselves, trusting they’ll meet challenges even if they don’t have all the answers right away.

“I always say that some people are inspired by learning, and then there are others who need to be inspired before they can learn,” he said. “I’m a product of shop classes where some people hear an engine roar or smell a welder’s smoke to realize that, ‘Wow, I can do this.’ I like to say in my speech when I give these scholarships out – ‘Find what inspires you, because if you can find what inspires you, there’s no stopping you.’”

For more on Daigle Brothers, visit daiglebrothers.com.

‘It’s about being a champion, a convener and a catalyst’

‘It’s about being a champion, a convener and a catalyst’ Solar plant shines light on process, benefits

Solar plant shines light on process, benefits