March 3, 2025

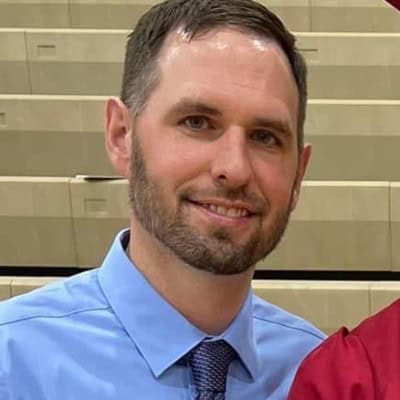

ARGONNE – A metal fabricator with decades of experience said he happened upon business ownership after a favor to a friend turned into a full-time venture.

Jeff Wagoner – founder and owner of D Rock Grizzly in Argonne – said he initially got into fabrication and welding through an annual off-road race.

“I got started out working with one of those race teams,” he said. “I started out just sweeping the floor and doing whatever I could to be part of it. Then – over several years – I worked my way into fabrication of the race chassis, and that’s what started me in fabrication.”

After fabricating chassis for “many years,” Wagoner said the cross-country race schedule became a bit tough to manage as he tried to balance work and family.

“That’s a tough schedule,” he said. “You’re all over the country (and work) a lot of hours. So then my friends approached me – because I’d been a fabricator by then for 20 years – looking for a piece of equipment to be built.”

That piece of equipment was a grizzly – which Wagoner said is a tool used by landscapers, quarry operators and property owners alike to screen rocks and debris from dirt and gravel.

“They couldn’t find one anywhere in the Midwest that they wanted,” he said. “They knew what they wanted, and they asked me to build it.”

Wagoner said his friends appreciated the quality of their grizzly so much that they became business partners – encouraging him to pursue a business in welding grizzlies and even funding the steel he used to fabricate the first-ever D Rock grizzly.

“After we built theirs, we were talking about the need, and I said I didn’t really have any money to get started,” he said. “At that time, I just got married, I was building a house and I didn’t have any extra cash, so they offered to put up the money for the steel for the very first D Rock grizzly… We put it for sale by my home, by the highway.”

That grizzly sold, Wagoner said, and soon after he received “two (more) orders, then two orders again, then eight and then 20.”

“We saw a hole in the Midwest where people were looking for these things, and they wanted a quality one,” he said. “They didn’t want a cheap one. They wanted something they could stand behind and that would last many years of service and abuse.”

Wagoner said he soon discovered it wasn’t just people in the Midwest who were searching for quality grizzlies, as he began fielding orders from “New York to Alaska” – prompting him to officially launch the business in 2017.

Grizzlies for jobs of every size

D Rock Grizzly, according to its website (drockgrizzly.com), sells five different rock grizzlies – the TR6, LR8, MR10, HD and Ripper models – all varying in sized and capability.

Wagoner said the reason for different sized models is “there’s different size equipment and there’s different sized material that people are screening.”

“So, the first thing we do when someone calls is we ask them what size equipment they’re using, because these models of grizzlies are sized to match whatever loader or excavator they’re using,” he said. “

Rock quarries, Wagoner said, will traditionally purchase the largest model – the Ripper – “because they have the biggest equipment, they have the biggest rocks, they have the biggest everything.”

“You have to build a grizzly to be durable enough to last in that environment, so that’s the reason for the biggest size,” he said.

Wagoner said he also sells a lot of grizzlies to landowners for their own personal use.

“(For) our smallest model, a lot of landowners grab that one. People who have hunting cabins with a tractor or a small skid steer,” he said. “They have these cabins with big, long roads to get into them, four-wheeler trails and all this land that they have to keep up. It gets real muddy, and the trails and roadways get nasty. They can (buy) our small grizzly, take it to their cabin, and they can dig into any bank that they have on the property – if it has good gravel in it – and they can screen the big rocks out and fix their roads, fix their trails and everything around our cabin. So that’s become very popular.”

Wagoner said the second thing prospective customers are asked is the size of the materials they are looking to screen.

“The rocks you want to screen out, are they over two feet or under two feet?” he said. “If your machine bucket is 10 feet wide, we can’t stick you with a small model, because the bucket won’t fit inside of it (to pick it up and move it around).”

The amount of space in between each screening bar of a grizzly, Wagoner said, is determined by what size of rock a customer wants to filter out of the dirt or gravel they are excavating

“The distance between the bars is what people are after, because if you have three-inch bar space between the grizzly bars, three-inch rocks and below will fall through there,” he said.

Wagoner said all of D Rock Grizzly’s base models are built using fixed screening bars – meaning they can’t be moved – but customers have the option to add what he calls a cleaning bar on every grizzly (with the exception of the smallest TR6 model).

“(With the cleaning bar) every other bar on the grizzly bar screen lifts up so it clears anything that’s stuck between the bars,” he said. “You can bump that with your machine bucket, and it lifts up every other bar so nothing’s ever stuck between the bars.”

Wagoner said he introduced that option after discovering that people were damaging their grizzlies trying to dislodge stuck rocks.

“People have all different ideas of how to get them out of there, and what they end up doing is wrecking stuff trying to get the rocks out by picking them out with their machine and sledge hammers and all different ways,” he said. “So we decided to add that as an option, where you can just come in with your machine, hit the bumpers inside and it lifts up every other bar so those rocks free themselves.”

Another option Wagoner said D Rock Grizzly offers is adjustable screening bars.

“They can take four bolts out of every bar, and they can change that bar space to one-, two-, three-, four-, five- or six-inches between the bars,” he said.

That option, Wagoner said, is exclusive to D Rock Grizzly’s LR8 and MR10 models because those are built to be used with skid steers and are popular among landscapers.

“They’ll use a grizzly screen for a whole bunch of different applications,” he said. “One day they’ll be screening mulch or topsoil. The next day, they’ll be sizing rocks for retaining walls.”

Wagoner said there are two reasons why the adjustable bar option is only offered on the medium size grizzly models.

The first, he said, is that he found customers purchasing the larger models “never even move the bars.”

“The second issue is the other companies that do provide adjustable bars in that size model, they can’t keep the bolts tight,” he said. “When you get into the bigger machines, the bigger rocks – the bigger everything – people are just busting bolts constantly. We saw that as an issue with our competitors and we never even went that (down) route on our own, because we replace four or five grizzlies a year in the larger models of other people who bought adjustables (from our competitors) and broke them. So we only offer the adjustable bar in our skid steer models because everything’s smaller (and) not so abusive.”

New building, products on horizon

Operating out of a shop adjacent to his home, Wagoner said the D Rock Grizzly team consists of four people – himself, his oldest son and two additional welders.

Wagoner said his team builds 40 grizzlies a year on average, and because the product is of such high quality, D Rock Grizzly’s customers rarely need to replace them.

“We don’t have very many issues at all as far as replacing (broken grizzlies),” he said. “When people call us, it’s never to replace (a grizzly), it’s to add another one.”

Because his current shop “is tight” on space, Wagoner said he and his employees work in shifts.

“We have to do two shifts,” he said. “My son and I work all day, and then the other two guys come in the afternoon and work into the evening. So that’s how it works right now.”

As the business continues to grow, Wagoner said he’s looking to move D Rock Grizzly into a larger building – expanding its footprint and capabilities.

“The shop is small,” he said. “We are currently doing quotes for a new building. We’re either going to build a building or buy one here locally. We’re weighing our options right now.”

The larger space will also bring the opportunity to build on D Rock Grizzly’s product offerings – something Wagoner said is already in the works.

“As we’ve gained a foothold in the grizzly market, we are moving into vibratory screens,” he said. “Basically, it’s the same thing we do now, but it has a motor on it that shakes and vibrates. It’s (used) more for (screening) finer material… So you’re shaking out even finer material with no rocks in it at all.”

Right now, Wagoner said he and his team are in the design phase for the new vibratory screens, but anticipate having them market-ready by July.

Good products = busy business

Though D Rock Grizzly began operation eight years ago, Wagoner said it didn’t become his full-time job until 2022.

“I did it part-time for the first six years, it was nights and weekends,” he said. “Then from 2020 to 2022, I was in the shop every night and every weekend, all the time. Then in ’22 I finally decided that it was time to go full time.”

The decision to walk away from his job at the time was a difficult one, as Wagoner said he had “the dream job” in his county.

“With three kids and a wife and a family to support, it was a big risk,” he said.

Wagoner said the catalyst for the change came after the Fourth of July when he had a three-day weekend for the holiday, but, unfortunately, couldn’t spend it with his family as he had grizzly orders to fulfill.

“I worked all weekend, and my family was out having fun and all that stuff,” he said. “(Monday night), I just walked up our stairs in the living room, my wife was sitting there, and… I just said, ‘I’m done.’ And she’s like, ‘What do you mean you’re done?’ And I’m like, ‘I’m done with my job… and I don’t want to quit this…’ The next day, I went in and put in my two weeks and never looked back.”

In the beginning, Wagoner said “it wasn’t so bad” balancing his full-time job and the business, but as orders started to ramp up, it quickly became unmanageable.

“People weren’t really in a hurry at the time because we were a new company, and they understood we were just getting going,” he said. “But then – after we grew and our reputation grew – people started to realize that we built a good product, and got a lot busier.”

Wagoner said people he sought advice from were skeptical about him leaving his job to pursue the business full-time – but three years later, he said D Rock Grizzly is not only surviving but thriving.

“I should have walked away a lot sooner (because) I would have gotten a lot of my time back,” he said. “But I had that dream job, and everybody I talked to thought I was crazy to try to walk away from that to go try this – or not try it, but go for it, (because) I don’t believe in trying, I believe in doing.”

‘I don’t believe in trying, I believe in doing’

‘I don’t believe in trying, I believe in doing’ WAF named U.S. Manufacturing Leadership Award finalist

WAF named U.S. Manufacturing Leadership Award finalist