November 1, 2023

DE PERE – The Foth Companies has a long and storied 85-year history – one Randall J. Homel, chief executive officer (CEO) and chair of the board of directors at Foth, said is both because of its innovative mindset and its team’s determination.

Homel said its a story of client partnerships, exemplary work ethic, steady growth and a unified, challenger spirit.

Where it all began

Foth’s humble beginning started in 1938 in three small rooms in the Columbus Building on the 400 block of East Walnut Street in Green Bay.

There, the company’s namesake, an electrical engineer named Herbert S. Foth, primarily provided municipal/infrastructure engineering work to the Green Bay area.

Fast forward 85 years, and Foth is now the largest scientific/engineering firm headquartered in Wisconsin (2121 Innovation Ct. in De Pere), with 28 locations across the United States and 670 employees.

Today, Homel said Foth consistently ranks in the top 100 largest design firms in the United States by Engineering News Record, solving engineering and manufacturing problems for communities and private industries in North America and across the globe.

And yet, even as the business’s reach has expanded, its headquarters remain in Northeast Wisconsin – which Homel said sets the tone and instills the cultural attributes that differentiate Foth from the competition.

It’s something Homel, who has been with the company for 44 years, serving the past decades as the company’s fifth CEO, said he knows intimately.

“The company has been part of my family since I was a kid with my dad working here,” he said. “So, I have been around this my whole life. It’s been awesome to see the evolution (of the company) from its humble beginnings.”

Homel said for him, and the company’s 213 member-owners, it’s largely a cultural thing – rooted in 18 attributes the company holds dear.

These, he said, include:

Being values-basedClient-centeredMember-ownedInfluentialInclusiveContinuously learningInnovativeCaringRelationship-buildingCollaborativeResults-focusedFlexibleSafety-mindedQuality-orientedTransparentProcess-drivenStrategicEthical

Those attributes, Homel said, live alongside the business’s focus on solving its clients’ toughest science and engineering challenges.

“I like to say we are in the partnership business,” he said. “Often, our clients pick us for the tough stuff, like how we work and then end up doing business with us (in other areas).”

Homel said Foth’s work falls into three broad types of solutions:

Infrastructure solutions (providing municipal/civil engineering often for governments, airports and private clients)Environmental solutions (public and private cleanups, both land and water)Production solutions (providing engineering, custom machines and turnkey installations to large consumer packaged goods manufacturing companies)

About half the company’s business, Homel said, is in production solutions with the other half fairly evenly split between infrastructure and environmental solutions.

Randy Homel

“We started in infrastructure and it’s a natural linkage for companies in our space to grow into environmental solutions,” he said. “But the unique connection is what we call production solutions. Our evolution to include (diverse) markets is intentional for stability.”

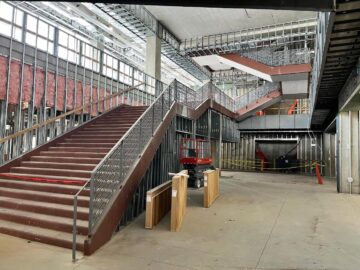

A case in point

Foth also does its work by market – ranging from airports to waterfront/marine and everything in between – but Homel said it differentiates itself in how it’s set up internally to accommodate the work.

For example, he said, a project at Conagra Brands vegetable processing plant in Waseca, Minnesota, involved all three aspects of the business.

“That’s a project we brought everything to bear on versus (the client) having to hire a bunch of companies,” he said. “It required all three areas in a big way.”

The $250-plus million faculty replacement project, Homel said, required design-build, engineering for product manufacturing and water and wastewater elements.

Homel said the deadline was unrelenting, as it needed to be completed in time for harvest.

And, it tapped into many of Foth’s areas of expertise.

Though many construction projects focus on the building itself, Homel said this project required design-build services because it also required optimizing the layout of the equipment.

As such, he said the project led with engineering and identified a single source of accountability in contrast to a traditional approach of using a general contractor to manage the project and subcontractors, which was unlikely to get the project done in time for harvest.

Instead, he said having a single point of contact for the project’s 250 contractors on site each day – as Foth did – and more than 1,100 people involved simplified Conagra’s risk management responsibilities and oversight of the build.

Homel said it was also an exercise in Foth tapping resources across multiple service lines and disciplines in an efficient manner.

The multidisciplinary nature of the project team, he said, worked in Conagra’s favor despite challenges, including a global pandemic, supply chain issues, commodity price fluctuations and weather challenges.

To everyone’s liking, Homel said the project was completed on time and on budget, allowing Conagra Brands’ new processing plant to produce 185 million pounds of corn, peas and rice every year while simultaneously reducing water consumption at the plant by 25%.

“We show we care as much about their problems as they do,” he said. “It’s what we do every day to help our clients do what they do, playing some key roles in part of their bigger picture strategies.”

Homel said unwavering determination, collaboration and communication are often at the heart of that.

“What we do as engineers and scientists here is deal with problems, and it can sometimes be overwhelming,” he said. “Some will give up, but our clients know we never give up.”

Another project Foth was also involved in since its beginning, Homel said, was the Fox River PCB cleanup project – which highlighted persistence and focus for long-term results.

Homel said Foth was involved in the first test project and designed a solution.

“We’ve been married to that for 28 years now, and we are now in long-term monitoring having been hired to monitor the river for 30 years now that the cleanup is done,” he said. “We cut out teeth on that project locally and have since done that (work) all over the country, in Oregon, Washington state, New York and more.”

Another recent, local project Foth has been involved in, Homel said, is a big ship project for Fincantieri Marinette Marine that’s nearly completed.

It involves the creation of a ship lift that will be able to lift a new class of ship for the U.S. Navy, which is too big to side-launch as they do with most ships.

“We are weeks away from completion on that, and it’s something we started in 2018,” Homel said.

At the heart of Foth

Homel said like many other employers, Foth is experiencing hiring challenges – though company differentiators drive both talent attraction and retention.

“People ask, ‘Is it tough finding people?’” he said. “And it is – it always has been because what we do is in high demand and always has been. But we find the right folks because what we do is cool stuff. We have challenging projects and a variety of projects, and then once they’re here, there’s the culture.”

Homel said many engineers or scientists pursue opportunities for a company doing “x,” – whereas working for a consulting company, such as Foth, allows them to work on “x,” “y” and “z.”

“Folks in our industry tend to get jazzed by the variety of markets and services and projects we work on,” he said.

There is both a technical variety in terms of the work, Homel said, as well as an environment that has always been flexible and is increasingly so after COVID-19.

Flexibility, he said, has always been an integral part of Foth’s culture.

“We’ve always had it out of necessity because our clients demand a lot of us,” he said. “They are asked to do some tough things, some unusual things and the best way to respond to that is to provide professional flexibility.”

Pre-COVID, Homel said, allowed employees to work in hybrid or fully-remote roles, but the number who routinely work in those capacities ramped up significantly during and after the pandemic.

“Company practice has allowed for it, tech has allowed for it and our members have sharpened their collaboration skills to allow for it,” he said. “A more distributed workforce requires more communication and collaboration among our members, and our leadership team continues to focus on how we can sharpen and build relationships (among) those who aren’t physically near each other.”

Homel said Foth is also intentional about offering part-time work – whether to accommodate individuals who need a part-time schedule or those who want to move incrementally into retirement.

“Part of that strategy is to retain knowledge workers versus having them (outright) retire,” he said. “It’s a way they can step back, allowing the transfer of knowledge and providing another form of flexibility.”

Innovation spurs progress, growth

Speaking of technology, Homel said it also plays a fundamental role in the business’s innovative mindset and its longevity.

As the company prepares to celebrate its 85th anniversary, Hormel said it is also anticipating its 100th anniversary in 15 years, which will include opening a time capsule buried at its current location.

Randall Homel said virtual reality and augmented reality bridge the gap between design and construction phases – improving alignment and communication across multi-discipline teams, whether near or far. Photo Courtesy of The Foth Companies

Among other things, Homel’s own BlackBerry is housed in the capsule, which he said is a nod to how swiftly technology and other innovation evolves.

“At Foth, we are intentional users of new technology because not all new things are a good idea,” he said.

Artificial intelligence (AI) is one of those things right now, and Homel said the company is testing its use in more of an experimental sense and with great care – though they are also receptive to innovation, be it in a technology or a new practice.

In fact, Homel said Foth was one of the first engineering firms to introduce virtual reality (VR) in 2015, and VR capabilities took off from there.

Perhaps one of the most beneficial ways this technology benefited the business and its clients, Homel said, happened during the height of COVID-19, using three models within virtual reality for design reviews.

“It came in handy during COVID when we couldn’t get people together, and we found a way with Microsoft Teams for everyone to look at what somebody wearing goggles was viewing,” he said.

Homel said it also garnered the attention of Deloitte’s 2022 Wisconsin 75™, on which Foth ranked No. 64 among the 75 largest private companies in Wisconsin based on sales revenue.

Foth also received a distinguished performer award in the innovation category that recognizes a company whose new product and/or service, business process or technology has positively impacted how an organization can work, do business or serve customers.

“We received that innovation award specifically for our use of AR and VR during COVID,” Homel said.

Homel said innovativeness permeates the entire organization – from company practices like that to integrating technology into how it does business.

For example, Foth is the first to scan every highway in the State of Washington from a survey-grade standpoint, which has required driving a truck with a scanner on it to capture pictures and perform survey-grade measurements for use in infrastructure projects.

From that, they’re building a model of every highway in the state.

This is employing the use of mobile LiDAR scanning (MLS), which Homel said Foth invested in to provide clients with richer data, especially with projects that span a long and linear space – including highways, city streets, multi-level roadways, railroad corridors, tunnels, airport infrastructure, etc.

And because Foth’s MLS system collects billions of data points during the scanning process, Homel said it can serve as a digital databank of information that can be extracted as needed without doing additional surveys.

“(For Washington), this information will come in handy when they prepare to make design changes to the highways,” he said.

Paying homage to its roots

With much of its legacy stemming from and in Northeast Wisconsin, Homel said Foth has had and continues to have a strong bond with the community.

That, he said, is evident in the business’s commitment to STEM education that began with the Einstein Project and extends to an endowed scholarship at the University of Wisconsin-Green Bay (UWGB) and other STEM-focused initiatives.

Homel said former CEO Steve Van Dyke and former member Dave Turiff and his wife, Cecelia, worked together to start the Einstein Project, a nonprofit organization that supports science education in the classroom.

They believed science could be more engaging and impactful in the classroom if industry partners teamed up with the education sector.

Since then, Foth has had a continued presence and involvement on their board of directors.

Foth’s design-build project at Conagra Brands vegetable processing plan in Waseca, Minnesota, increased capacity for processing peas, corn and rice, while remaining focused on food and employee safety. Photo Courtesy of The Foth Companies

“We are strong advocates of the engineering program at UWGB as well as (The Foth Companies Endowed Scholarship for Engineering) there because so much of our focus and energy is rooted in science and engineering,” Homel said. “We want to grow interest in those fields with kids of all ages.”

Homel said it is particularly fitting the annual scholarships are at the institution to which Foth provided planning and infrastructure work for the site development of UWGB, which included more than 700 acres.

Foth, he said, has also had a hand in other significant area projects, including:

Austin Straubel International Airport – designing the airfield in the 1940s, the company’s first major client.Bringing television airwaves to Green Bay – laying out plans for TV transmission towers built on Scray’s Hill, southwest of Green Bay. Foth did additional work as commercial television added other stations as well.

The next era

At the end of the day, Homel said Foth’s business model has set the 85-year-old company up for success – averaging 10% growth annually, stable and intentional growth.

“We’re committed to growth, but growth in a way that is not only profitable but stable for our clients and our members,” he said.

The U.S. Census Bureau reports only about 12% of companies are older than 26 years, and only a handful last 100 years.

“If you look at our industry, there are others with this longevity, but many are a ‘mishmash’ of other companies buying each other out and merging into a new company,” he said.

Even after 44 years, Homel said he’s “jazzed” to come to the office to partake in positioning Foth for the next 85 years.

“It’s been cool to watch the evolution of the company from such humble beginnings,” he said. “It keeps me excited, it keeps the 213 owners who own the company excited. It’s a big cultural thing that’s ours and nobody else’s.”

Daigle Brothers – Building Wisconsin one steel column at a time

Daigle Brothers – Building Wisconsin one steel column at a time Farm to School benefits students, local businesses

Farm to School benefits students, local businesses