May 5, 2025

FOND DU LAC – As a woman- and minority-owned small business, Owner Maria Perl said Spark Ops Metalworks was born as a result of an opportunity she and her husband Bryan saw in the market.

Established in 2022, the Fond du Lac-based company – according to its website (sparkopsmetalworks.com) – started out manufacturing truss systems for large events like the Super Bowl, UFC, PGA and more – as well as structural elements for Road America and aerospace maintenance platforms for Embraer in Macon, Georgia.

Today, Spark Ops Metalworks is a full-service metal fabrication and manufacturing company that provides custom metal solutions across various industries.

As the company continues to make a name for itself, CEO Tom Ackerman said over the past year, Spark Ops has gone through the state and federal certification process to be recognized as a women- and minority-owned company – which, he said, means it can now accept government contracts.

“A lot of companies in the manufacturing world will use a portion of the fabrication needs toward hiring minority-owned businesses if they have government contracts – presuming the businesses can still match the quality needed,” he said.

Though Spark Ops is still in the early stages of its strategic move toward being recognized as a women-owned company, Perl said, so far, so good.

“Once you step into government contracts, the first thing they tell you is you have to be patient,” she said. “We have had a very good record of getting the federal certification in (that past) 11 months.”

When the certification process was complete, Perl said it was a big celebration for the entire company.

“I look at it as a tool to help knock on doors and put our feet in a forward motion to help leverage Spark Ops as a formidable partner for any company in need of fabrication,” she said.

Because she is a woman and a minority in a sector that is traditionally male, Perl said she’s been able to redefine her own perspectives on what’s possible.

After graduating with a Doctor in Medicine degree in Cuba, Perl said she came to the United States and started working as a waitress – eventually working her way up.

Fast forward to 2025 and Perl is making waves in the manufacturing industry in Wisconsin.

“Now I see that I can do several things in different industries just with a different mindset,” she said. “You need to be surrounded by a great team, you need to improve yourself and you need to be proactive and add all your skills into the bucket.”

Ackerman said Perl’s medical background has helped guide the company and decisions because of her ability to ask critical questions and find critical solutions.

Creating a new product

Perl said though she and Bryan have been in the fabrication business for a while, it was limited to the truss side of the business.

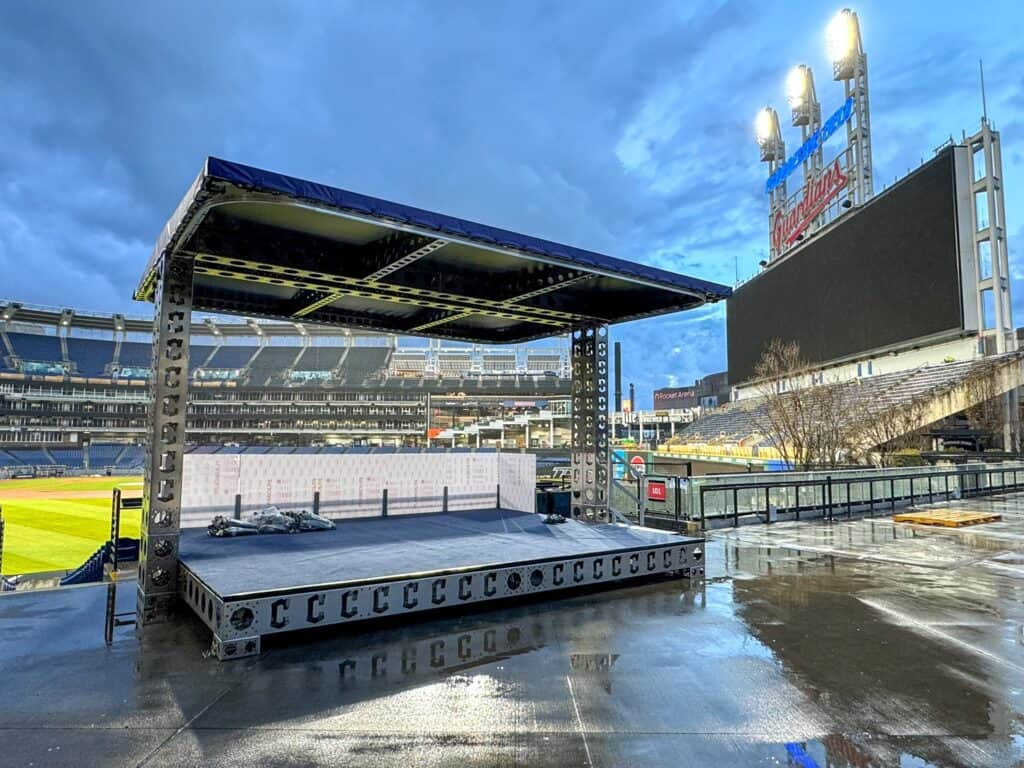

“At the same time, we were in the product development phase for a new product, the iCube, which is a revolutionary modular space for live events, commercial use, government and humanitarian needs and more,” she said.

Ackerman said the iCube, or Infinite Cube, is a product exclusively produced by Spark Ops for Infinite Structures, which has a history in the event industry.

“With the introduction of iCube, you now have a big shift in production at Spark Ops,” he said. “What was once nearly 100% truss production is now roughly 25% of production for 2025 as iCube continues to grow.”

Perl said it’s a similar idea to a truss in that “it’s a temporary structure that can pivot, be ready any time, any place, with a single structure going up in just a few hours.”

According to infinitestructures.com, each iCube provides 160 feet of floor space and 10 feet of height, and can be infinitely combined and even stacked with additional iCubes.

“We offer different levels of versatility for almost any industry because they’re reusable, reconfigurable and more sustainable because of that,” she said.

Additionally, Ackerman said, it’s economically friendly.

“Because of how iCube is shipped and erected, it has almost no competition,” he said. “The only competition for iCube would be a similarly sized container, which may show up at an event, but it’s one container per truckload. Whereas you can ship up to seven iCube units, all parts for assembly included, on one truckload.”

Ackerman said one of Spark Ops’ first orders – which exceeded 100 iCubes – was last November from the NFL for the 2025 Super Bowl.

“The iCube configurations are a nice solution because it’s not a tent, and it feels like a traditional (building) environment, yet at the same time, feels more professional,” he said.

The product is gaining traction, so much so that Ackerman and Perl said some governmental organizations have been calling asking about it.

“Right now, it’s walking before we run with government contracts for the company, but we can see the knocking on the door as we look forward to 2026,” they said.

A ‘can do’ mentality makes it possible

Perl said what’s made this all possible is the “can do” mentality the entire company has.

“I know we’ve had the good fortune of people knocking on our door asking if we can create a product, and the answer is almost always ‘yes,’” she said. “We don’t make excuses – we make it happen. We’re on the proactive side of things.”

Though the technology and ability of typical container-type set-ups are getting more sophisticated, Ackerman said he is of the mindset that the look, form and function of Spark Ops’ collapsible configuration can go hand in hand with the iCube’s growth to outpace changes to containers.

“Traditionally, container spaces can be clumsy, and the tent world has certainly gotten more sophisticated,” he said. “They can look big and they’re scenic for sure, but they’re also susceptible to the elements. Considering it snowed before the Super Bowl, a tent would have been a difficult environment for broadcasters.”

Ultimately, Ackerman said the product was born out of a need.

“Many heads came together knowing there had to be a better way to produce something of the sort,” he said. “The product went from a design to full function test and production within a year.”

Because the product is collapsible and portable, Ackerman said it has advantages in different and unique ways.

“The superstructure really allows for any configuration of the units, being able to utilize doors, windows, heat, air and full electrical, too,” he said. “From production sets to bedrooms and even bathrooms, the market has been extremely receptive to where the company can take the iCube.”

Ackerman said the feedback from the Super Bowl has been “excellent.”

“Growth is happening organically,” he said. “The product is being seen and the governments are becoming aware of this product and wondering what the humanitarian uses could be.”

Technology of the iCube

Perl said the innovation behind the iCube might look simple – “after all, it’s a roof, a base and four poles – (but) they’ve been able to incorporate multiple new elements into.”

“Integration of modern technology within iCube is certainly one reason our customers are loving them,” she said. “One of those elements is the lights, which can be controlled via cell phone. You can make them any color you need, you can dim them, choose which row or side you want and if you have multiple cubes together, you can control all of them individually and conveniently.”

Ackerman said the roof has built-in rain gutters, so water can flow down to the ground.

“However, one of the newer developments we’re working on is making the iCube even more watertight,” he said. “The current glass used is tested to wind speeds of more than 100 miles per hour, so in theory, and through more testing, one or more of these cubes could be inside a hurricane zone and give protection to workers or items.”

Ackerman said an example of this could be a forest range where you can’t have a permanent structure, but you need a viable working space to house a research facility in the middle of nowhere.

“Now you’ve got a bathroom, possibly bedrooms, a place where park rangers can be safe for months at a time if needed,” he said.

Looking to the future

Currently, Ackerman said Spark Ops has four different production locations – including its headquarters at 463 Cedar St. in Fond du Lac.

“Desiring to keep everything under one roof, we recently purchased land in the Aeronautical Industrial Park just west of Fond du Lac airport,” he said. “This new facility will be about 150,000 square feet.”

Perl said she is optimistic about this move, as it will provide an opportunity for Spark Ops to improve efficiency while getting everything under one roof.

Ackerman said with the new facility, Spark Ops will be able to triple its capacity.

“That’s from employee size to production as a result,” he said.

Furthermore, Ackerman said market forecasting doesn’t see the iCube product going away anytime soon.

“Sure, at some point, there will be competition, but first is first – you can’t take that away, and that’s what gets you in doors,” he said. “We feel confident we’ll be able to stand on our own two feet for quality and what we produce. We don’t see a short run on the need, and this is looking out five to 10 years – especially in the humanitarian side of things.”

Ackerman said the company is looking to champion a market and a brand that is built in America and offers a relatively quick and easy solution, one cube at a time.

“Though iCube changed the strategy of Spark Ops because of the need, that doesn’t change our original core business of truss and platforms,” Perl said. “Rather, the addition of the production of iCube is what’s encouraging the desire for the larger headquarters that will ultimately give more opportunities to people and more jobs.”

WAF named U.S. Manufacturing Leadership Award finalist

WAF named U.S. Manufacturing Leadership Award finalist New owners at the helm of Tribute Brewing Company

New owners at the helm of Tribute Brewing Company