April 7, 2025

MARINETTE – KS Large Bore Pistons touts that its power keeps the world moving, with its pistons hard at work for clients throughout North America.

Tobias Heinold, senior customer manager, said the global company has had a presence in Marinette since 1999, joining the original KS Large Bore Pistons location in Neckarsulm, Germany.

The impetus for the Marinette location, Heinold said, was to serve the market for customers in the U.S. and Canada with products manufactured in the United States.

Today, he said KS Large Bore Pistons is known for serving as one of the world’s leading designers and manufacturers of large-bore pistons.

Heinold said these pistons are used in engines – particularly large, medium-speed diesel and gas engines, with bores (cylinder diameters) ranging from 130-400 mm manufactured in Marinette.

Ultimately, he said the pistons are designed to power ships, locomotives and stationary power plants sustainably and efficiently.

“It’s all designed to the needs of the customer – nothing is off the shelf,” he said. “Every customer and every engine is different, depending on temperature and other variables including what they are trying to achieve. We create a tailor-made solution for every application.”

Heinold said KS Large Bore Pistons stands not only for customization but also for quality in the market.

Though there are a few competitors in the large bore piston market in Europe, Heinold said no one else serves the U.S. and Canadian market the way KS Large Bore Pistons does.

“We are known for quality and short lead times – those are key drivers,” he said. “We can go on-site or (we) are near our customers, many of which are in the Rust Belt of the United States or around Lake Erie. It depends on where customers have plants – that may be anywhere in the United States, Canada and North America.”

What the pistons are made of, Heinold said, is contingent on customer requirements.

If it’s a low-power output, he said KS Large Bore Pistons may opt for aluminum; if it’s a higher-power output, steel may be in order.

Regardless of the material, Heinold said KS Large Bore Pistons is relied upon for precision and innovation as well as solutions to drive a future less dependent on fossil fuels through engines that are powerful, eco-friendly and built to last.

Decades of development

Heinold said the business has grown since establishing its presence in Marinette 26 years ago.

When KS Large Bore Pistons opened that location, he said it produced about 1,000 pistons per month.

Today, Heinold said the business produces 200 pistons per day in the plant that was initially expanded in 2015 and again in 2023.

The most recent expansion, Heinold said, occurred after KS Large Bore Pistons became part of the Swedish Koncentra Group, which members of the Marinette team said was a change in ownership but a focus on continuity of business.

The 35,000-square-foot expansion of the plant, the team said, accommodated the integration of a steel piston line and new equipment.

“Those investments were focused on serving the renewable and sustainable energy markets,” Quality Manager Angie Thomas said.

Megan Davis, human resources manager, said during that acquisition, KS Large Bore Pistons broke away from another plant in town focused on small-bore pistons – a move that required the team to hire its own team members in certain areas that were previously shared, such as information technology, human resources and finance.

“That was a big part – building those departments on our own,” Davis said. “That’s when we took on the new line to build products for heavy-duty trucks, broadening our customer base as a result.”

With the resulting increase in business, Heinold said, has come an increase in employees.

At the end of 2022, prior to the sale, he said KS Large Bore Pistons had about 66 employees.

Today, Heinold said it employs 133 employees, to accommodate the growing business, as well as growth in the mining/construction industry segment and rail segment.

“Those are really strong with the rail market never having these numbers before,” he said. “It is stronger than it’s ever been before. The market need is the result of what the U.S. infrastructure is doing now, as well as customer demands – those correlate to our business.”

As a result, Heinold said KS Large Bore Pistons’ revenue has doubled – yet the company’s culture of continuous improvement has never taken a backseat.

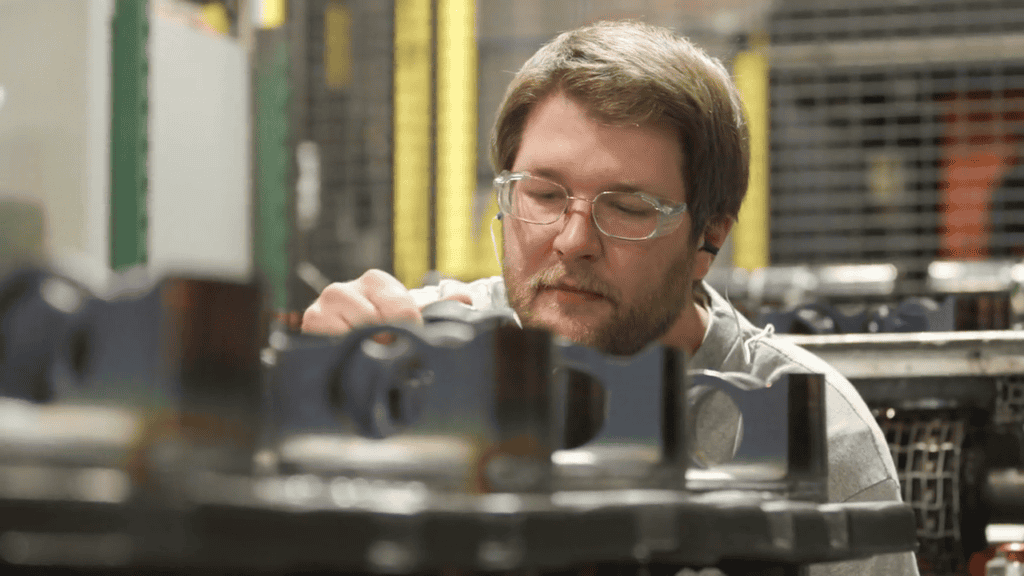

Instead, Thomas said the culture plays a significant role, particularly as large bore work can never be fully automated.

“With locomotive pistons and power generation pistons, it’s one piece at a time and it’s not high volume,” she said. “We have some operations that are 10 minutes long and some that are an hour long, and they’re all involved in making one piece. It’s difficult to put a lot of technology into some aspects of that process.”

Keeping continuous improvement top of mind is the focus of the company’s well-received Great Effort Means Success (GEMS) program, Davis said, through which employees are encouraged to submit quality, safety, productivity and other improvement ideas for consideration.

After investigating submissions, she said selected submissions are eligible for an award in addition to implementation.

“People get really excited about it, which is really neat,” Davis said. “I don’t think we have gone a month without at least one GEM.”

The employee populace in the Marinette location, she said, is diverse, with about half the employees being women.

In contrast, Davis said the German location employs about two women in its production facility.

“There are some powerful, knowledgeable women in (the Marinette) facility,” she said.

Davis said the level of knowledge required to do the work has admittedly been a challenge when it comes to hiring.

Piston manufacturing, she said, is highly specialized and requires more sophisticated and prolonged machining experience, knowledge or training.

Fortunately, Davis said when people join the KS Large Bore Pistons team, they tend to remain a part of it for quite some time.

She said the team also includes many employees who are siblings, aunts/uncles, nieces/nephews, etc. within it.

“We have a lot of employees who have had a really positive experience here, and they share that,” she said.

Davis said the Marinette location also has beneficial resources in its sister facilities in Germany and China (which was established in 2012) when it comes to sharing best practices.

Though the knowledge-sharing is global, Heinold said the business has worked to source as much locally and from the U.S. market, especially during the current economic climate.

“That’s something we have always done, and it helps a lot in the current economic environment,” he said. “We recognize tariffs could change at a moment’s notice.”

Visit ks-lbp.com to learn more.

Aspirus Wausau Hospital completes Emergency Department expansion

Aspirus Wausau Hospital completes Emergency Department expansion Bringing the convenience of the city to the middle of nowhere

Bringing the convenience of the city to the middle of nowhere