August 18, 2025

RIVER FALLS – Jake Wagner, co-owner of South Ridge Ranch Bacon in River Falls, said when choosing a mid-life crisis, for him and wife, Stacey, it was either buy a sports car or start smoking meats.

He said he and Stacey, chose to smoke meat – more specifically, bacon.

“No one told me they would cost about the same each month,” he laughed.

Nestled in the heart of River Falls, the Wagners said they have a simple belief – bacon should be an experience.

Beginning operations in 2023, the couple said they craft small batches of bacon that go beyond the ordinary.

“We blend traditional curing methods with innovative flavors, bringing you bacon made in the community we love,” Jake said. “At South Ridge Ranch, quality is at the heart of everything we do.”

Perhaps similar to how many breweries begin operations with a homebrew kit, Jake said in a way, that’s how South Ridge Ranch got its start.

“This whole endeavor started about a decade ago,” he said. “My wife won a smoker at work, so we started smoking meat. Then, about two years ago, I was working for a major corporation in the Twin Cities, and they went through a massive layoff – I was one of those who were laid off.”

Though he had been making and giving out bacon to family and friends for years, Jake said “the constant ‘you should sell this’ from those family and friends finally struck a little deeper as I was laid off from my corporate job.”

“The opportunity presented itself, and as a family, we decided it was time to try,” he said.

Jake said Stacey was also instrumental in helping get things started.

“My son and I were going on a mountain bike trip for four or five days, and when we got back, Stacey said, ‘Are you ready?’” he said. “I looked at her and said, ‘Ready for what?’”

Jake laughed because he said he didn’t think his wife meant starting the bacon business would come so soon.

“In July [2023], we got to work on finding a location, getting all the correct paperwork and licensing and the initial equipment purchases,” he said. “We had our first sale Dec. 1 – [later that year].”

Stacey said after her husband got laid off, it was a good time for her “to be a bit pushy,” because it was the perfect time to start their business.

“I think Jake was a little shocked I wanted to try it so quickly, but we didn’t want to look back in five years and wonder,” she said. “If we were ever going to do this, it was the perfect time to figure out if we could actually make it work. We’re really proud of the product and excited about it, so we’re happy that it has blossomed into what it is.”

Jake said when they initially got going, they joined an entrepreneurial training program that helped them bring all of their ideas together.

“We came up with a one-, two- and three-year business plan,” he said. “In year one, we had more sales than we anticipated in year three – it’s been very well received. Also, in the timeframe, we’ve pivoted a couple of different times on what we were doing when we first started. You have to pivot to what customers want.”

Finding a space

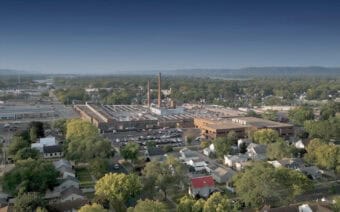

When looking for a space, the couple said the St. Croix Valley Business Innovation Center (1091 Sutherland Ave.) in River Falls made sense – and it’s worked out great.

“Inside the space, there are offices, cubicles and areas for light industrial work,” Jake said. “About four or five years ago, they added a commercial kitchen… We own all of the equipment, and you’re just leasing floor space, essentially.”

Jake said even though the businesses in the innovation center vary, they still have lots in common with the other owners.

“I am here every single day,” he said. “On top of the bacon business, I still have a contract job, so I lease out a spot in the cubicle area, too – to do my data job.”

Jake said “obviously, it’s convenient” to have space at the innovation center for both jobs.

“It’s kind of funny – I go back and forth between the kitchen and my desk,” he laughed. “The company I contract through knows about my bacon business, and it’s been a great partnership. I can smoke bacon in the morning and then walk around a couple of doors, and I’m back at my desk working on data.”

Stacey said she frequents the innovation center about five days per week.

“I have a day job as well, but we spend the majority of our free time working at the bacon business,” she said. “For most of what we do, we sell at the farmers’ markets or different events and fairs. We do the online piece where people can order and pick up at the innovation center as well. One of us is usually here a good portion of the time, but we don’t have an actual storefront.”

Though the current process seems to be a well-oiled operation, starting Nov. 1, Jake said he will be jumping into the bacon business full-time.

“We are expecting more growth,” he said. “As of Nov. 1, I put a hard stop on my [data job] contract. We’ve seen growth from year one into year two. In year two, we actually have some history, whereas in the first year, we were just starting and didn’t know a whole lot.”

Jake said they have one part-time employee and a paid intern – the couple’s son.

“He’s big into mountain biking, and instead of him getting a job somewhere else, I said, ‘Why don’t you come and work for the bacon business?’” he said. “This way, when he races, he doesn’t need to ask another employer off from work.”

Jake said with the innovation center, the goal is to utilize the space for three to five years before moving on to a new location.

“I’ll be signing my third one-year lease in a couple of months,” he said. “The ultimate goal is to have our own spot, but we’re not quite there yet. We still have a few more steps. We have to go through more growth over the next two years, and then we’ll see what happens.”

A family touch

Besides the artisan approach to their bacon, Stacey said she thinks there is another reason people are flocking to South Ridge Ranch.

“I think they really like that we’re a family business,” she said. “We affectionately refer to [our family helpers] as unpaid interns. My parents and Jake’s parents are involved, and our kids are involved. We also get help from friends. It’s the personal side of our business – we promote and talk with people daily about that.”

Though they can currently handle almost everything in-house with the help of family, Jake said the eventual goal is to employ people outside of the family.

“We want to get to that point where we’re bringing in employees and putting more hours into the actual processing of our product,” he said.

Big differences

The couple said South Ridge Ranch Bacon is “different” than store-bought bacon – as it goes through a seven-to-10-day dry-curing process.

“If you think of the dry rub that goes on your chicken or your ribs, it’s similar to what we do, except it’s a seven-to-10-day process,” Stacey said. “It really changes the way the bacon tastes and behaves. We like to play around with different flavors – things that complement your real-world dishes you’re going to use bacon in.”

Jake said for the most part, store-bought bacon shrinks down to as much as half its original size when cooked.

“Our bacon will shrink some, but maybe only 20%,” he said. “With our dry-curing process, the flavors actually get into the bacon. We’re not coating it after the fact.”

After South Ridge Ranch Bacon is cured, Jake said it is then placed in a controlled environment for the duration of the curing process.

“During this time, the curing mixture draws out moisture and enhances flavor,” he said. “The dry-curing process offers more room for customization. Additional ingredients like maple syrup, herbs, spices or even a touch of smokiness can be incorporated during the curing, creating a wide range of flavor options.”

Jake said store-bought bacon is usually wet-cured, which involves injecting the meat with a curing solution that contains salt, sugar and nitrites – then quickly processed and packaged for sale.

“This wet-curing method is faster and more efficient for large-scale production,” he said. “The wet-curing process doesn’t allow the flavors to develop as intensely as in dry-cured bacon. The texture is often softer and can release more moisture when cooked.”

According to its website (southridgeranchbacon.com), popular South Ridge Ranch Bacon flavors include Masala Love, 1788 Black Pepper, Honey Habanero, Sweet and Smoky, Maple and Chesapeake Coastal.

“The most Wisconsin bacon I ever made was for Father’s Day,” Jake said. “I made brandy old-fashioned bacon. We’ve also done a dill pickle bacon.”

For more on South Ridge Ranch Bacon, visit the website or find it on social media.

Where food tells a story and farmers are rock stars

Where food tells a story and farmers are rock stars Farm to School benefits students, local businesses

Farm to School benefits students, local businesses