September 29, 2025

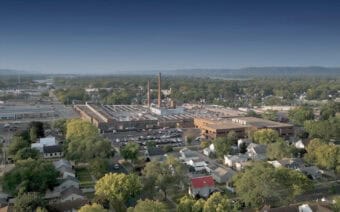

WESTBY – A $14 million expansion is underway at Westby Cooperative Creamery as the company ramps up cottage cheese production to meet growing demand.

Emily Bialkowski – sales and marketing director at Westby, located at 206 S. Main St. – said the culture cheese product manufacturer is the only cottage cheese producer in the dairy state.

“We are cultured dairy specialists – meaning we do cottage cheese, sour cream, yogurts and sour cream-based dips – and we are the only cottage cheese manufacturer in the State of Wisconsin,” she said. “So, we are really cottage cheese specialists.”

Though there is no lack of creameries across Wisconsin, Bialkowski said it’s typical for businesses to specialize their offerings.

“You get really good at a few things, and you stick to what you’re really good at… because each cheese has its own requirements and peculiarities, if you will,” she said.

As the Badger State’s only cottage cheese manufacturer, Bialkowski said Westby Cooperative Creamery’s recent expansion was a necessary move to keep pace with rising demand.

“Cottage cheese demand across the United States is incredible,” she said. “Store-brand sales are up 6.5% compared to last year, while some of the national brands saw increases of more than 25% as far as sales are concerned. So, there’s tremendous demand for cottage cheese.”

The demand is so incredible, Bialkowski said, that Westby Creamery is “currently oversold on cottage cheese.”

“We can’t fill the orders we’re already getting, so the expansion will address consumer and our customer demand,” she said.

New equipment = less physical labor

Another factor driving the expansion, Bialkowski said, was the aging condition of the creamery’s existing cottage cheese equipment.

“The cottage cheese making equipment that we currently have is aging, and we want to swap it out before it hits end of life,” she said. “In the process of bringing in new equipment, we’re also going to gain some efficiencies, as far as less human labor.”

Westby’s current equipment, Bialkowski said, includes open, stainless-steel vessels employees must stand over to regularly stir in ingredients and move cheese around.

“Three thousand pounds of cottage cheese is very heavy,” she said, “so there’s a lot of physical labor to the cottage cheese making process today.”

Bialkowski said the cooperative’s new equipment, when installed, will be fully enclosed and will not require a human touch to stir and move the cottage cheese.

“The new production and the new equipment will eliminate almost all of that very physical labor,” she said.

An additional value to the new equipment, Bialkowski said, is the pace at which Westby will be able to produce cottage cheese.

“Current production time to create a vat of cottage cheese is 16 hours,” she said. “We’re going to reduce that to eight hours. So, we’re going to be able to crank out more cottage cheese within a given amount of time.”

The amount each vat will yield, Bialkowski said, will also increase.

“We should get about 10% more cottage cheese from the same amount of milk,” she said. “So, there are a lot of gains in updating the equipment now, simultaneously, while demand for the product is very high. It’s kind of a win-win.”

Bialkowski said the new enclosed vats will also turn (or, in this case, churn) finished product faster than the current open vats – aiding in the creamery’s increased production needs.

“These new enclosed vats will top out at 5,500 pounds, but they will be making things faster,” she said. “So, we’re able to double our production within the same amount.”

Other key upgrades to the facility include:

- A new food-grade room within the existing facility (approximately 80 feet by 40 feet)

- Two cream tanks (10,000-gallon capacity)

- One new 30,000-gallon milk silo, sourced in Wisconsin

- Upgraded refrigeration, sanitation and auxiliary equipment

And though the equipment won’t require regular attention from its employees anymore, Bialkowski said the expansion project will not result in any lost jobs at Westby Creamery.

Productive cows

Bialkowski said roughly 60-65% of Westby Creamery’s business is private-label – meaning the cooperative is making other cottage cheese brands’ products.

“Then, a small portion is also done for our own label,” she said. “Some of our clients have proprietary blends, and some of our clients use our recommended recipe.”

Currently, Bialkowski said the expansion project is in its preliminary planning phase.

“There are other ancillary things we’ll need to make sure [are in place],” she said. “There’s piping across the plant that gets product to and from. [Then] you have to have pumps, you have to have packaging [and] you have to have a way to get cottage cheese to the packager. So, all of that equipment is in the process of being selected.”

Though at the time of the interview with The Business News an official beginning to the construction phase of the project had not yet been scheduled, Bialkowski said Westby Creamery’s goal would be to complete its expansion by next fall.

“We will maintain production as construction is going on in our current cottage cheese room,” she said. “The new room is a separate part of our facility, so it’s going to be completely walled off and secured so that employees don’t accidentally stumble into a construction zone… and then when the new equipment is ready, we’ll slowly bring it online.”

The $14 million project, Bialkowski said, is the “largest investment” Westby Creamery has made in the business to date.

“We’ve been around since 1903,” she said. “So, through the century, we definitely have had other large projects, but this obviously is the largest.”

Bialkowski said Westby Cooperative Creamery lives up to its designation as it is owned by the farms that supply the creamery with its milk.

“We are a farmer-owned cooperative, meaning the 85 farms that send their milk to the creamery own the business,” she said. “The average herd size for our farmers is 50 head of cattle – 50 milking cows. So, truly, this is a legacy that supports small, family farming.”

Though family-owned and -operated dairy farms have been decreasing over the years, Bialkowski said milk production in the state has stayed the same.

“Throughout the history of the creamery, the size of how many farms own the business has ebbed and flowed,” she said, “but one thing that is noteworthy is there are fewer dairy farms making the same, if not more, milk than, say, 30 years ago. So, because of genetics and nutrition, dairy cows today are very productive.”

As long as farmers’ cows remain productive milk producers, Bialkowski said Westby Cooperative Creamery will be around to preserve what makes Wisconsin the dairy state.

“We’re ensuring the future of our small, family farms,” she said.

For more on Westby Cooperative Creamery, visit its Facebook page or website – westbycreamery.com.

From the Minor Leagues in Appleton to the big stage

From the Minor Leagues in Appleton to the big stage ‘Think of it as the Oscars of our industry’

‘Think of it as the Oscars of our industry’