January 5, 2026

NEKOOSA – Nekoosa Coated Products – a subsidiary of M2S Group – has earned Green Masters status from the Wisconsin Sustainable Business Council (SBC), highlighting both its decades-long paper manufacturing legacy and commitment to sustainable practices.

Michelle McEachen – M2S Group’s corporate sustainability engineer – said achieving Green Masters status is “an incredibly big honor.”

“I couldn’t be prouder of our team at M2S group and Nekoosa,” she said.

McEachen said understanding Nekoosa’s participation in the Green Masters Program requires knowing about M2S Group’s three other business units: Appvion, Decorative Films and Iconex.

“For the M2S group, collectively, across our four business units, we have more than 115 years of experience in the industry and have 15 global locations,” she said. “M2S is a material science and innovation company.”

McEachen said Appleton-based Appvion has been a part of the Green Masters Program for more than 11 years, setting the standard for its sister companies.

“That’s how we really heard about Green Masters – Appvion has been participating in the program for many years,” she said. “A few years ago, we submitted for Nekoosa, and we’ve continued doing that annually.”

McEachen said the SBC has been a great resource for Nekoosa and M2S Group’s other three business units.

“As far as sustainability, it’s been great to find local contacts and networks, etc., through the SBC,” she said.

McEachen said sustainability is deeply embedded in Nekoosa’s operations, and achieving Green Masters status reflects the consistent efforts of teams across the company.

“It’s not just a single project – sustainability at M2S and Nekoosa isn’t just a marketing effort…, it’s really a part of how we operate daily,” she said.

Green Masters

SBC Executive Director Jessy Servi Ortiz said Nekoosa Coated Products – and Appvion – are among 21 companies statewide to earn Green Masters status.

For more than 15 years, Ortiz said Green Masters Program recognition has been a hallmark for Wisconsin businesses leading sustainable change.

In its 15-plus-year history, she said the program has helped nearly 400 Wisconsin businesses accelerate sustainability throughout their value chain.

“The Green Masters Program is a comprehensive tool that helps businesses define, prioritize, measure and manage their sustainability performance, integrating sustainable practices into their core operations,” she said. “Aligned with internationally recognized standards, it drives continuous improvement and sustainable success.”

Ortiz said the Green Masters Program enables companies of all sizes and sectors to improve their performance in environmental, social and governance (ESG) impact areas that are meaningful to their business and stakeholders.

“The Green Masters Program categorizes participants into four status levels that reflect the degree to which sustainability has been integrated into their business model: Adapting, Advancing, Maturing and Green Master,” she said. “Green Masters status signifies that the organization has identified and is effectively managing its material sustainability issues and performance related to those issues, takes a comprehensive approach to sustainability and is actively leading the transformation to a more sustainable society.”

For more information about SBC programs and the Green Masters Program, visit wisconsinsustainability.com.

Nekoosa’s sustainability efforts

Over the last year, McEachen said M2S Group and Nekoosa have made significant strides in sustainability, supported by the executive team across all four of the company’s business units.

“It’s great to have their support and really help cascade it through every department,” she said. “Our CEO, Paul Charapata, said he wants sustainability not just to be owned by himself or me but really incorporated into every single team member’s goals. If you’re a production worker or in R&D (research and development), you know what sustainability means and how that ties into your role.”

In the last 12 months, McEachen said they developed the “Materials for Tomorrow” framework, which integrates sustainability into every department and is structured around six pillars:

- Safety and wellness

- Eco-innovation

- Low environmental impact

- Nurturing team potential

- Community empowerment

- Sustainable supply chains

“Nekoosa has always had a sustainability mindset, but now we’ve really formalized it, and we’re tracking it,” she said. “We have a dedicated resource that makes sure all the hard work we’re doing is being captured.”

Energy reduction, McEachen said, plays a key role in the company’s overall sustainability strategy.

“Year to date, through October, we’ve reduced our consumption across MS2 Groups by 17%,” she said. “That’s significant, and it really shows that it’s not just me – it’s a whole team effort. We’re meeting with each site monthly, having energy reduction and waste calls and talking about our open projects.”

McEachen said M2S Group also encourages employees to share ideas on ways the company can further improve sustainability.

“We have a lot of communication with our employees by utilizing our production TVs, employee newsletters and talking about it in our operational meetings,” she said. “New this year, we sent out our annual report to each team member’s house so they could see it.”

McEachen said efforts also include educating and engaging employees, with sustainability-focused videos created to support ongoing learning.

“Instead of someone just giving a boring talk or another email, we have those videos they can reference as well,” she said.

McEachen said the company performs exceptionally well in managing waste, which is another key sustainability metric they track.

“For example, at Nekoosa, they divert more than 94% of its manufacturing waste,” she said. “Annually, that’s four million pounds that is diverted from the landfill.”

McEachen said the company’s success in reducing waste reflects the dedication of its team members.

“We can say to them, ‘Hey, can we please put this in the correct bin,’ but they are the ones taking the extra time and doing it daily,” she said.

Another area of sustainability, McEachen said, is in equipment upgrades.

“When we looked at our air compressors, air leaks were a significant problem,” she said. “That’s an easy fix – fix what is causing the air leak. That’s one of our top opportunities across all of the sites. If you have air leaks, the compressors turn on more, which means they use more electricity.”

McEachen said energy audits typically show that about 25% of compressed air is lost in a converting facility like Nekoosa.

“It’s replacing hoses, replacing clamps or fixing the machine so they don’t leak the compressed air,” she said.

Into the future

McEachen said sustainability is constantly evolving, and the company aims to do more, including a 2030 goal to reduce energy usage by 25%.

“It’s not just the operational side of the business – it’s connected to every single department,” she said. “As we head into the new year, we ask ourselves, ‘How can we do better?’ We’ve really tried to formalize it – that’s part of my job.”

Community giving

Though sustainability remains a focus, McEachen said Nekoosa and M2S Group place equal importance on giving back to the community.

“Across our entire M2S group, we give back about $500,000 annually,” she said. “At Nekoosa and Appvion, our salaried team members – all office team members – get eight hours of paid time off to volunteer. Team members can bring their voices forward. If they have an organization that’s meaningful to them, they can submit a request.”

McEachen said the community giving also includes other campaigns and initiatives throughout the year.

“We recently had a gift-wrapping event for the holidays,” she said. “We also do food drives, back-to-school drives, etc. We’re big into using our platform to give back to local communities.”

For more on Nekoosa Coated Products and M2S Group, head to nekoosa.com and m2sgroup.com, respectively.

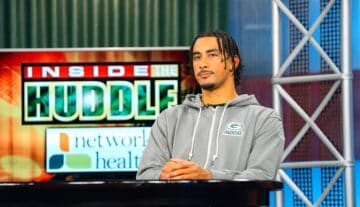

“Inside the Huddle” – Standing the test of time

“Inside the Huddle” – Standing the test of time Two WESTconsin Credit Union locations get new look at two of its locations

Two WESTconsin Credit Union locations get new look at two of its locations