September 29, 2025

BLOOMER – What started with three farm boys searching for a solution to ward off complaints of odorous smoke from an oven company, Mark Ruff, owner of Catalytic Combustion Corporation (CCC), said, has turned into much more.

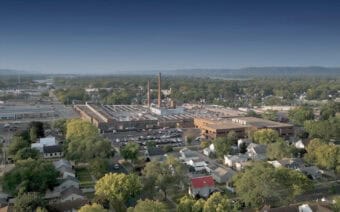

Seventy-five years later, Ruff said CCC remains a perfect fit for the small community of Bloomer – population 3,700 – helping to preserve its small-town values and strong Midwestern farm work ethic close to home.

A ‘catalyst’ for a business

Ruff said the company’s story begins with his great-grandparents’ journey from Germany to Milwaukee.

“During those times, you could homestead 40 acres up north,” he said. “My great-grandparents got to Milwaukee and found out about this homesteading act, so five brothers who came from Germany immigrated [to the Bloomer area] and then homesteaded [here].”

Ruff said CCC’s beginnings can be traced to the early 1940s, when several of the founding brothers were employed in manufacturing jobs that produced noticeable emissions.

“It was way before the EPA [Environmental Protection Agency] and regulations, but CCC basically was born because of neighborhood complaints,” he said. “The neighbors were complaining about smells that came from the manufacturing process at an oven plant.”

Because of the complaints, the three founders – Harold “Russ” Suter, Richard J. Ruff (Mark’s uncle) and Norbert C. Ruff (Mark’s father) – researched a cleaning apparatus on the exhaust system to combat smells and odors.

“The owners of the oven company basically said, ‘We’re an oven company – we don’t do anything with exhaust,’” Mark Ruff said. “Two of the founders – Richard and Russ – got talking about how to fix the problem while duck hunting in northern Michigan and came up with several different ways to clean up emissions.”

Ruff said that duck-hunting trip proved to be more than just a getaway – it was the spark that led to a breakthrough.

“Suter explained that a catalyst is basically – if you look it up in the dictionary – something that gets involved in a reaction but doesn’t get consumed in the process – it accelerates a reaction,” he said. “The three had the idea they could use precious metals – platinum and palladium – in the form of a catalyst to accelerate a reaction.”

In simple terms, Ruff said CCC manufactures specially engineered metal components coated with precious metals, which accelerate a chemical reaction – called catalysis – that transforms harmful exhaust molecules into harmless substances.

Once they had an idea in place, Ruff said the trio immediately began focusing on research and development to bring their solution to life.

“After a lot of trial and error, they basically developed the first all-metal catalyst for industrial air correction,” he said. “From farm boys to entrepreneurs, the three developed a catalyst and a catalytic oxidizer that could basically be installed on any type of process that emitted pollution.”

Ruff said CCC was officially incorporated in February 1950, with corporate headquarters, administration, sales and engineering based in Detroit, while manufacturing operations were established in Bloomer – the Ruff brothers’ hometown.

“The first location for CCC in Bloomer was leased space in the old Bloomer brewery building,” he said. “Over the first decade or so of business, they built the company and received contracts. They actually opened a catalyst manufacturing facility in Germany, too. They were listed in the August 1955 Popular Mechanics edition.”

To support the company’s growing operations, Ruff said a new catalyst manufacturing facility was built in Bloomer in 1957-58.

“This facility is still in use by Catalytic Combustion and has gone through many additions and improvements since its original construction,” he said.

By 1962, Ruff said the three founders had taken the company as far as they could financially with the resources they had – therefore leading to the merger with Universal Oil Products (UOP) and “became a division of the larger corporation.”

“A new fabrication manufacturing facility was constructed across from the [existing] catalyst shop in Bloomer,” he said. “This facility still exists in Bloomer but is now occupied by another company.”

Trying times

In 1963, both Suter and Richard passed away, marking what Ruff described as a difficult time for the company.

Ruff said his father, then 42, remained with UOP and worked there for an additional eight years.

“He got a little frustrated with corporate America, but they grew the company through the ’60s,” he said. “In the early ’70s, they made some corporate changes to where they were headed with the company, and it had some rocky times.”

By 1985, the company had significantly reduced its production team, dropping to just nine.

“It was announced that the Bloomer facility was going to close,” he said.

However, Ruff said the remaining CCC employees decided to buy the remaining assets of the company from UOP and give things a go on their own.

“They struggled at first to get going and had to mortgage their homes and farms to the local Bloomer bank to get started,” he said.

As time went on, Ruff said the new owners gained a deep understanding of what it takes to run the business.

“They learned about payroll, marketing, sales and engineering,” he said. “It was a struggle, but had those nine employees from the Bloomer area not bought the assets, CCC wouldn’t be here today.”

Still a family-owned business

During his roughly 12 years working in corporate America after college, Ruff said he traveled across the United States and became familiar with the exhaust emissions from printing presses, which was his field at the time.

“I got to the point with corporate America where I could see there were other facets to life,” he said. “I always enjoyed the Bloomer area – hunting, fishing, snowmobiling and having four seasons.”

Ruff said it was a love of his parents’ roots and those he eventually created and nurtured in Bloomer that inspired him to get involved with CCC.

“I picked up the phone and called one of the majority stockholders, Joseph ‘Bud’ Koehler,” he said. “Bud told me they were in the process of evaluating the company and realized their ages ranged from 48-68, and they really didn’t have the drive or the expertise to move the company forward. That started conversations about me [becoming] more involved in CCC.”

That conversation, Ruff said, marked the beginning of his deeper involvement with CCC, and he spent about two years learning the ins and outs of the company.

“I was able to accomplish a stock purchase over time of Catalytic Combustion,” he said.

At that time, Ruff said the company had about 11 employees, whereas today, that number is about 200.

“We have sales offices in Cheyenne, Wyoming; Albuquerque, New Mexico; Midland, Texas; Fort Worth, Texas; and Oklahoma City, Oklahoma, and have service centers in Pennsylvania,” he said. “We’re fortunate we’ve been able to grow the business.”

Catalyst examples

Ruff said there are countless examples of how CCC has expanded its reach into companies worldwide.

One such example, he said, is the national restaurant chain, Subway.

“When you go to Subway and have your sandwich toasted, we have developed the catalyst for the ovens [the restaurant] uses,” he said. “We have a catalyst in every oven in every Subway worldwide. It takes care of that toast smell when you bake bread. This allows Subway not to have to vent that oven or have an exhaust fan.”

Continuing its innovation, Ruff said CCC has created catalysts tailored for engine exhaust systems.

“We work with Indian Motorcycle, Kohler, Generac, CAT, Rolls-Royce, etc.,” he said. “We have emission control systems and locomotive prime power turbines for natural gas and do a lot of work right now with standby power, especially in the data center. We’re very diversified in our product offering, but it all comes back to air correction in different applications.”

In order to support these expanded products, Ruff said CCC has a full-service, in-house engineering team.

“I probably have more than 33 degreed engineers,” he said. “We’re heavy on chemical and chemical engineering because of the new coatings we develop. We have project managers, mechanical engineers, electrical engineers, etc. We design all of our own controls and also design a lot of our own production equipment. We have about 150,000 square feet of manufacturing space.”

Ruff said CCC’s products range from systems to control emissions from large manufacturers and power-generating operations to small catalysts that control emissions from household appliances and almost every application in between.

More specifically, he said industries served include:

- Power-generating industries

- Mission-critical power generation

- Gas compression

- Industrial emission control

- Off-highway engine exhaust

- Commercial cooking and consumer appliances

For more information, visit catalyticcombustion.com.

Homeschooling parents open The Homie Hub in Oshkosh

Homeschooling parents open The Homie Hub in Oshkosh Neapolitan pizza in the heart of Two Rivers

Neapolitan pizza in the heart of Two Rivers